New Paragraph

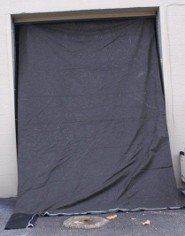

Geotextile Fabrics

Woven Stabilization Geotextile Fabric

Woven Monofilament Geotextile Fabric

High-Performance/High Strength Geotextile Fabric

NTPEP Certified Non-Woven Geotextile Fabrics (NTPEP = National Transportation Product Evaluation Program)

Non-Woven SEDI-BAG - Filter Bags / Dewatering Bags

NTPEP* CERTIFIED WOVEN STABILIZATION GEOTEXTILE FABRIC

Woven stabilization geotextiles are made from polypropylene as well, but the manufacturing process, product characteristics, and applications differ dramatically from those of nonwovens. Narrow strands of polypropylene tape are woven together during manufacturing, producing a sturdy fabric, but one with much less permeability than nonwovens. Commonly known as ground stabilization fabric, wovens are useful in separating less desirable subsoils from gravel or paved surfaces.

By effectively bridging over poorer-quality soils, they can provide savings in material costs and project life cycles. Perhaps the easiest way to understand the value of soil separation in roadway construction is to be aware that stone and gravel tend to sink into softer soils. A simple adage that road builders have used for years goes something like this: “Five pounds of stone on top of five pounds of mud equals ten pounds of mud.

NTPEP* CERTIFIED WOVEN MONOFILAMENT GEOTEXTILES

- Durable polypropylene yarns woven for dimensional stability and consistent pore size

- High permittivity and water flow rates

- Excellent resistance to UV degradation

NTPEP* CERTIFIED HIGH-PERFORMANCE / HIGH STRENGTH GEOTEXTILES

- High soil confinement for greater load distribution

- Durable and superior damage resistant

- High modulus, for immediate structural support

- Unique weave optimizing both strength and filtration properties